|

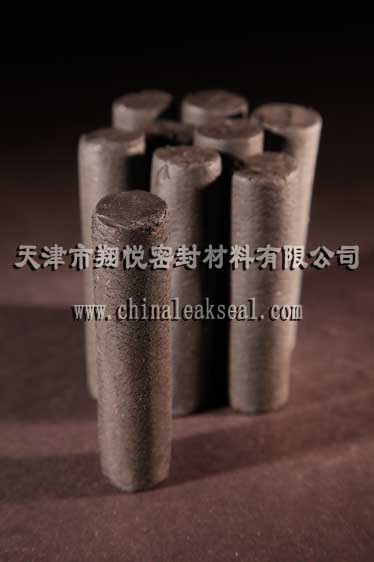

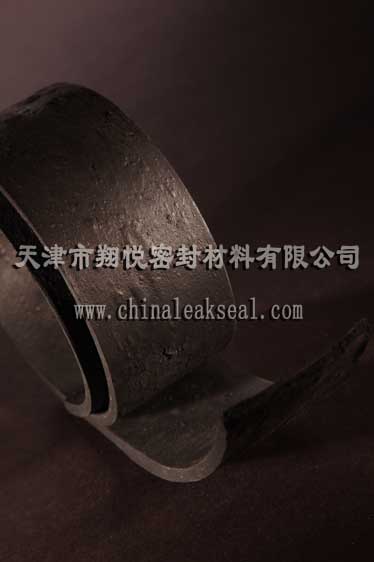

Model and Features of Sealant Model and Features of Sealant

Model and Application Scope of Sealant

Model |

Application Scope |

Storage Conditions |

( mm )

Specification (mm) |

Applicable Medium |

System Temperature

|

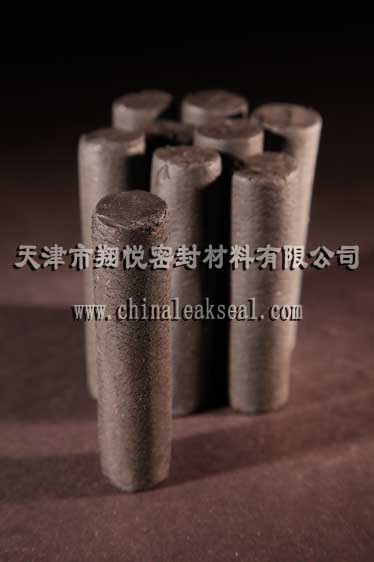

TXY-8 #

|

benzene and other strong soluble chemical gas, liquid and oil

|

-195 ~ 260 |

Sealed under normal temperature |

21 × 90 |

TXY-16#

|

oils, (high-temperature oil, petroleum, naphtha, sucking oil, diesel oil, transformer oil) high-temperature water, steam, alkali, muriatic acid, acetic acid(99%), alcohol, ketone, terphenyl, formaldehyde, ether and acetone |

< 680 |

Ditto |

21 × 90 |

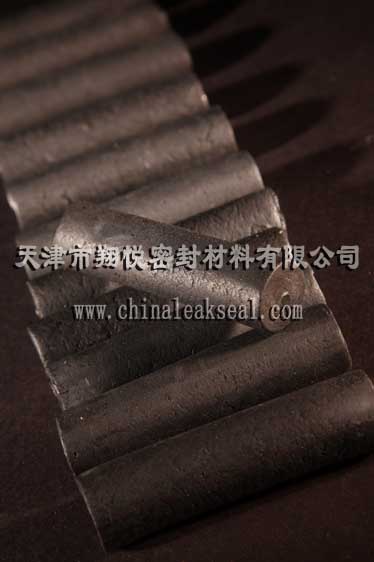

TXY-16# (flat)

|

oils, (high-temperature oil, petroleum, naphtha, sucking oil, diesel oil, transformer oil) high-temperature water, steam, alkali, muriatic acid, acetic acid(99%), alcohol, ketone, terphenyl, formaldehyde, ether and acetone |

< 680 |

Ditto |

21 × 90 |

TXY-18 #

|

Water, steam, air, oxygen, hydrogen, ammonia, coal gas, strong alkali, acetic acid, terphenyl, formaldehyde, ether, acetone, ester, oils (coal gas, petroleum, diesel oil, transformer oil, naphtha, sucking oil, heavy oil, etc.) muriatic acid, weak vitriol, superalkali, ammonia, etc. |

80 ~ 800 |

Ditto |

21 × 90 |

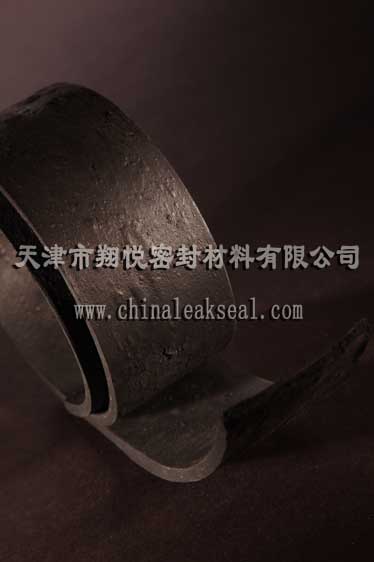

TXY-18 # (flat)

|

Water, steam, air, oxygen, hydrogen, ammonia, coal gas, strong alkali, acetic acid, terphenyl, formaldehyde, ether, acetone, ester, oils (coal gas, petroleum, diesel oil, transformer oil, naphtha, sucking oil, heavy oil, etc.) muriatic acid, weak vitriol, superalkali, ammonia, etc. |

80 ~ 800 |

Ditto |

21 × 90 |

TXY-18A # |

Water, steam, air, oxygen, hydrogen, ammonia, coal gas, strong alkali, acetic acid, terphenyl, formaldehyde, ether, acetone, ester, oils (coal gas, petroleum, diesel oil, transformer oil, naphtha, sucking oil, heavy oil, etc.) muriatic acid, weak vitriol, superalkali, ammonia, etc. |

150 ~ 900 |

Ditto |

21 × 90 |

TXY-18A # (flat)

|

Water, steam, air, oxygen, hydrogen, ammonia, coal gas, strong alkali, acetic acid, terphenyl, formaldehyde, ether, acetone, ester, oils (coal gas, petroleum, diesel oil, transformer oil, naphtha, sucking oil, heavy oil, etc.) muriatic acid, weak vitriol, superalkali, ammonia, etc. |

150 ~ 900 |

Ditto |

21 × 90 |

TXY-20 #

|

Fume, activator, ethane, and other special mediums |

80 ~ 720 |

Ditto |

21 × 90 |

2. Main performance of the sealant

After being pressed, the sealant could endure enough sealing specific pressure.

(4) Basic solidifying duration

(1) Temperature-resistant performance, pressure-proof capacity, and basic solidifying duration

In certain time and under certain temperature, the sealant maintain the stable intensity and elasticity.

(2) Medium-resistant performance

It refers that the sealant is, after contacting the medium for a long time, able to resist swelling and solvency.

(3) Pressure-proof performance

The sealant could, influenced by ambient temperature, shift from the plastic features to the elastomer, which could take some time before forming the tough elastomer.

Ambient temperature and basic solidifying duration of the sealant

Model of sealant |

Ambient temperature |

150 |

200 |

250 |

300 |

350 |

( min ) Basic solidifying duration (min) |

TXY - 16 # |

150 |

63 |

45 |

24 |

15 |

TXY - 18 # |

110 |

57 |

25 |

15 |

11 |

TXY - 20 # |

90 |

62 |

44 |

18 |

11 |

(5) Fluidity of technology

The sealant could, under certain pressure and temperature, become deformed and fill airproof cavity.

Applied Reference

1. When the valve packing box or high-temperature system flange connection gap is small, for sealing of leakage, the TXY-16# sealant should be adopted.

2. The serious leakage parts with high temperature and high pressure should adopt the TXY-18# for sealing, and attention should be paid to the coordination of the drive speed and the solidifying duration.

3. As for the grain or strong sticky medium sealing leakage, the edges should be set for the clamp to prevent the sealing airproof cavity.

4. As for the leakage sealing with high pressure and low temperature, the outer heating method could accelerate the solidification.

5. When the system temperature is lower than 250 , the TXY-18#, TXY-16# or TXY-8# sealant could be adopted to seal the leakage. After the injection is completed, the sealant should be replenished for pressing in the correct order so as to avoid the laxation of stress. |